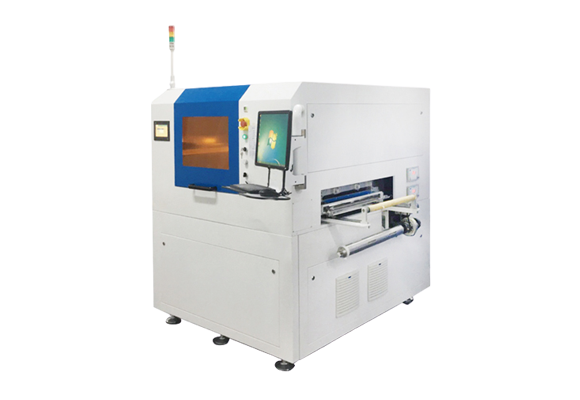

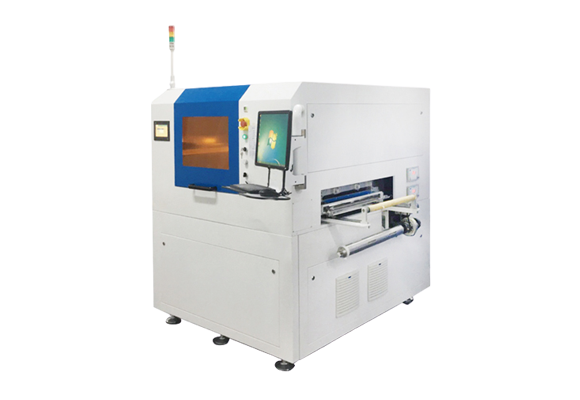

The high-end roll-to-roll cover film processing equipment meets the high-precision and high-quality requirements of customers at the same time. The full flight optical path and optimized loading and unloading devices save the customer on-site space.

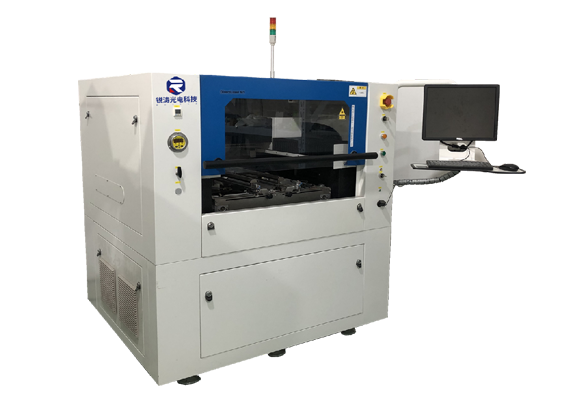

Direct data drive, immediate production, and rapid product import

There is an extension interface, which can be connected at any time, with a high degree of automation

Laser replaces molds to avoid distortion and break through mechanical limits

Picosecond cold cut removal, no heat, widen the variety of materials

Precise laser energy control, fixed depth and quantitative control, micron-level extreme structure

|

parameter |

RT-QG70L |

|

Laser output power |

15W (±2W) |

|

Laser wavelength |

355nm |

|

Maximum processing area |

510mm×640mm |

|

Device platform |

Granite platform, linear motor |

|

X/Y axis movement resolution |

0.1μm |

|

Repeatability |

±2μm |

|

Data processing software |

CircuitCAM 7 Standard |

|

Device driver software |

DreamCreaTor 3 |

|

Automatic loading and unloading system |

Matching |

|

Camera target alignment system |

Matching |

|

Industrial vacuum system |

Matching |

|

Equipment size (W x H x D) |

2,100mm×1,800mm×2,400mm |

|

equipment weight |

2,500kg |

|

power supply |

380VAC/ 50Hz, 3.0kW |

|

Ambient temperature |

22℃±2℃ |

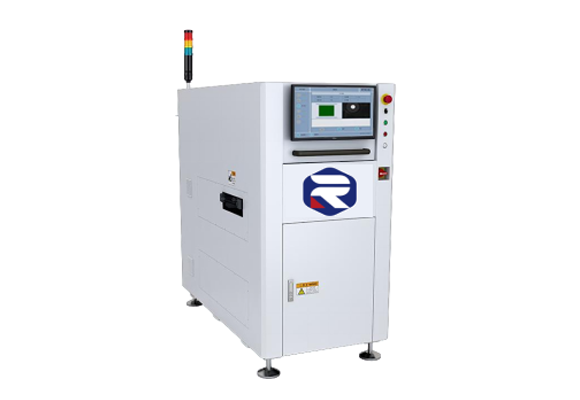

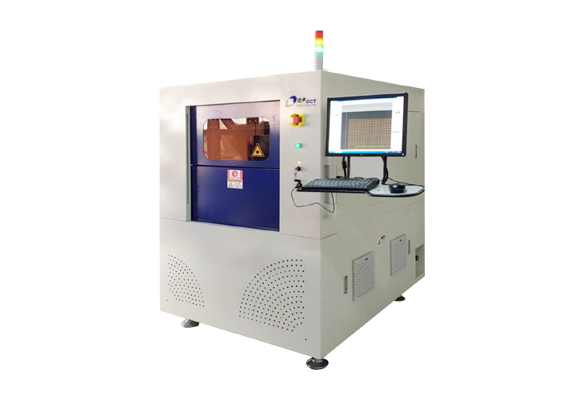

Precision laser marking machine RT-LM450T

Roll-to-roll high-speed ultraviolet laser cutting

Ultra-precision fiber laser cutting machine RT-SFL

High precision CO2 cutting machine RT-CLC4050

Precision fiber laser cutting machine RT-PELC68

Automatic film tearing machine RT-FPCS1

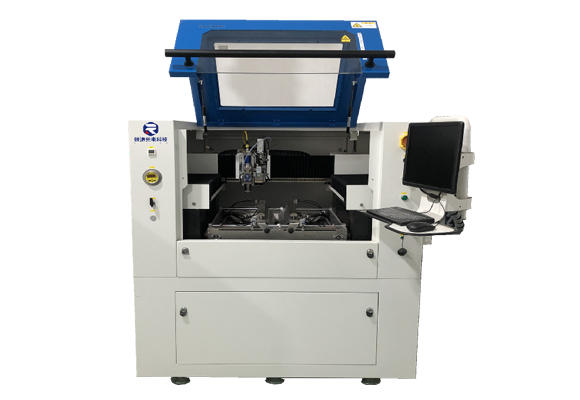

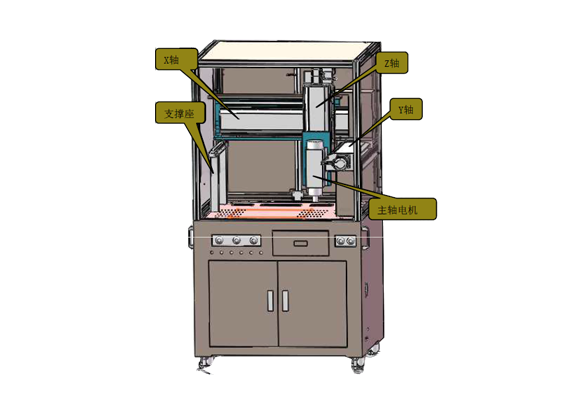

Milling machine

Ultraviolet laser precision machining system Direc

Scan us

Scan us